- This topic has 72 replies, 13 voices, and was last updated 7 years, 11 months ago by

FlyerInHi.

-

AuthorPosts

-

January 16, 2017 at 9:34 PM #804936January 17, 2017 at 12:34 AM #804937

ucodegen

Participant[quote=moneymaker]I put a ball valve in many years ago but used shark bite fittings as I did not want to use torches (oxy acetalene) as that was all I had at the time. had no problems but did have to have the water department replace their valve as it was defective at the street, they put a ball valve in as well after freezing the line with liquid nitrogen, talk about working quickly, they had to finish before the line thawed.[/quote]

I missed this comment. Many of the ball valves don’t like to be soldered because of the seat. If you look in through the end, you can see that the seat around many of them is a plastic – teflon like material that is probably not too happy getting a lot of heat.

[quote=flu]

I don’t know if I would use PEX on potable water. I don’t think there has been any studies done if it is safe for drinking….then again, PVC isn’t exactly good either and lots of houses run PVC.[/quote]

You can use PEX on potable water. It tends to be used on R-O water because it is resistant to corrosion. Pure R-O water can eat metal pipes; copper and galvanized.[quote=flu]

The concerning part is the bottom elbows. Yes, there appears to be two of them.[/quote]

Thats the little ‘dance’ to get away from the wall for the valves and regulator.

[quote=flu]

Any change of attack? I think the bottom part of the drywall needs to be removed. It’s probably going to get destroyed anyway with any sort of heat to the pipe…I’m thinking maybe remove both elbows at the bottom and just have a clean pipe running up from the ground to work with…[/quote]

That may make it harder. I still suggest seeing if you can just repair/clean out the valve first. Anyway, most of the ball valves are going to be ‘threaded’ on vs sweated. I also see that comments on the one HD sweated ball valve are not very good. Check the lengths of any of the replacement items before going all the way down to the vertical pipe. I would also be careful of getting that joint closer to the foundation or further out from the wall – it makes it more likely to be hit by something. You might be able to get by with replacing the second of the connected elbows with something like this: http://www.homedepot.com/p/NIBCO-3-4-in-Lead-Free-Copper-Silicon-Alloy-Pressure-90-Degree-C-x-M-Elbow-C707-4-LF/202029387 which would give you threads for the ball valve. The portion to the pressure regulator would also need to be changed, which would mean something like this: http://www.homedepot.com/p/Everbilt-3-4-in-Copper-Pressure-C-x-MPT-Male-Adapter-C604/100345906?MERCH=REC-_-PIPHorizontal1_rr-_-202029387-_-100345906-_-N to connect to the ball valve from the top. I am assuming 3/4″, but there are also 1″ products for the same.

[quote=flu]

I also measured the pressure on my pipes. It looks to be around 80-82 PSI…Ouch…I guess it’s been that way for awhile now…[/quote] That could either be an adjustment on the regulator, the regulator not sealing – causing pressure creep when there is no flow, or regulator diaphragm being shot. Watch the pressure when a valve is slowly opened. Does it drop and then get to a more normal pressure? If so, then the regulator is not sealing and may need replacement. If it stays at 80+, try using the nut to drop the pressure. From what I remember, tightening is less pressure. Be careful, there is a jam nut and the housing is plastic – don’t force things. If the regulator does not change the pressure on adjusting – then it needs an overhaul – probably easier to replace unless you know how to do the teardown and rebuild.Have fun – be careful – be safe.. don’t flood the garage ;-P

Oh yes, when loosening the compression fittings, stabilize the regulator so you don’t transmit torque through the pipe. It looks like you can put a large crescent or monkey wrench on the brass end of the center body of the regulator.

January 18, 2017 at 1:27 AM #804951exsdgal

ParticipantFinally a thread I can actually add-on to 🙂

Recently completed a similar task, but chose to leave the old regulator and inoperable shut-off valve intact. Here is the end result – (sorry about the debris and couple of messy solders)

[img_assist|nid=26181|title=valve|desc=|link=none|align=left|width=466|height=600]

Lots of good info in the previous posts. Hobie I will have to steal the wonder bread trick, and give the squirt bottles some rest. Here are some of the tools that made the soldering work a bit easier.

[img_assist|nid=26179|title=solder-parts|desc=|link=none|align=left|width=408|height=538]

After working with different solders, these days I swear by this one – https://www.lowes.com/pd/Worthington-16-oz-Lead-Free-Copper-Pipe-Solder/3819167. They melt like butter and provide a pretty leak free joins. A generous amount of water soluble flux (purchased at Fergusons) at the fittings end also helps. Couple of precautionary steps included wrapping the new and old regulators with dripping moist towels to avoid any heat damage, 2) the wall covered with a few layers of aluminum foil sheets to avoid flame burns. In this particular project, there was a bit of struggle connecting to the old section, which resulted in some flame burns on the wall!

flu – you can do it!

January 18, 2017 at 6:17 AM #804952Anonymous

GuestHow much would a plumber charge to do this?

January 18, 2017 at 7:15 AM #804953 CoronitaParticipant

CoronitaParticipant[quote=harvey]How much would a plumber charge to do this?[/quote]

I think about $300-400, according to one plumber I contacted, not including parts.

The regulator is about $110, the valve about $20, and brass fittings/pipe coupler about $30. So about $160….That’s assuming you source your own parts. Plumbers markup the parts they source.

The cheapest price for a quality Watt regulator I could find was $103, online.

Watts LF25AUB Lead-Free Pressure Regulator 1" Solder Double Union

It’s almost the same as the one home depot is selling for about $130 after taxes

http://www.homedepot.com/p/Watts-1-in-Lead-Free-Brass-FPT-x-FPT-Water-Pressure-Reducing-Valve-1-LF25AUB-Z3/203804614

The difference is just the fittings at the ends… The one I’m buying online has two unions sweat connectors like my current regulator. The home depot version has a FPT threaded union on one side, and fixed FPT threaded on the other.

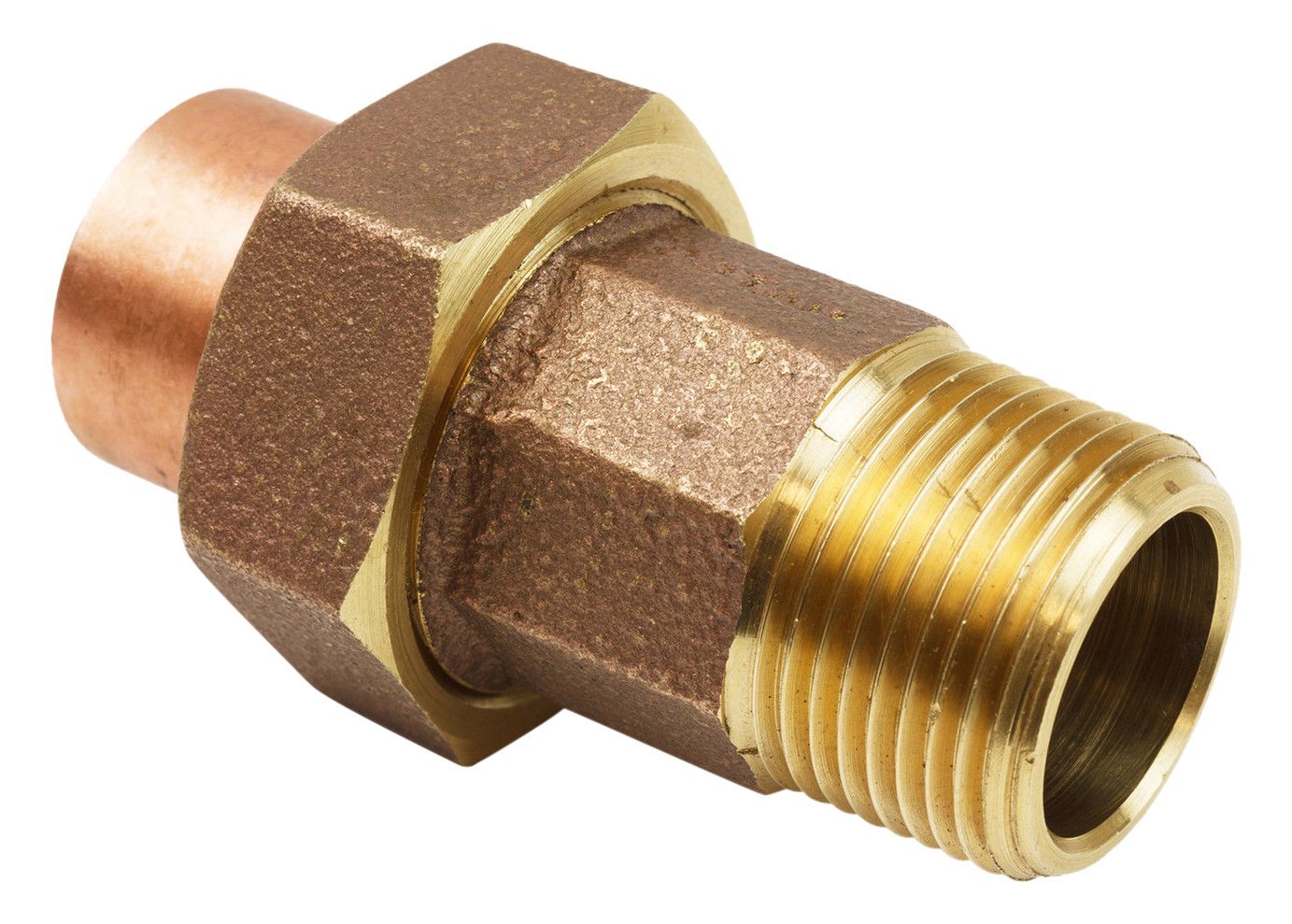

For future serviceability, I think I want to have one with a union on both sides.2. The valve I plan on getting for $30

It’s threaded on both sides but I’m thinking of adding this union on the side connected to the inflow pipe…..

And then on the outflow side, use a sweat to threaded male NPT adapter to connect the valve to the regulator.

I wish they had a 1″ valve with a union at the end, so I wouldn’t need to attach a separate union…

So there will be 3 union. One between the ground pipe and the valve. And two on both sides of the regulator… This should allow me to remove both the valve and the regulator in the future without needing to resolder…

The problem i see is that if I put everything together, I think the length will be longer than currently the distance between the inflow pipe and the one that goes into the wall….So I might need to get creative and run the valve horizontally to the left, the regulator vertical, and a pipe at the top back to the right into the wall, like half a rectangle….

I’m actually excited about doing this now. I get to learn something new…

I’m sick of working on my car after it caught on fire, lol.

January 18, 2017 at 7:21 AM #804954 CoronitaParticipant

CoronitaParticipantexsdgal,

Thanks for encouragement. Looks like a good job.

January 18, 2017 at 8:31 AM #804955exsdgal

Participantflu, thanks! I did enjoy doing this repair. Was nervous but it was fun when all done. I bought most of the fittings from supplyhouse.com. I will look at my invoices and post the items later tonight.

A quick note, my original inlet feed was like yours, for simplicity bypassed old line and created a new junction through the cutout wall for the city line connection. You can see the old inlet covered by the paper towel just below the old shutoff valve.

January 18, 2017 at 11:41 AM #804961FlyerInHi

Guestexsdgal, why leave the old components in place. The perfectionist in me doesn’t like this for aesthetic reason. You did the work already, it’s just a pipe and elbow extra.

Flu, I recommend a Kevlar shield. It stays nice and cool.

Why get a threaded valve?Just get the solder kind. So much easier, and you have more room for adjustment. I never replaced a regulator…do they all have threaded connections? I know that you want future serviceability but once you learn how to solder, that is the serviceability. Threads get corroded, the sizes will no longer match, etc… just buy everything new and solder..

Or is there is no leak, just leave good enough alone. I think flood control smart valves are coming to maket.

I’m pretty sure you don’t have home warranty. But for those who do, the insurance company (such as American Home Shield) should repair for the deductible. They may refuse to do the regulator if it’s still working but the valve would be replaced.

January 18, 2017 at 11:46 AM #804962 CoronitaParticipant

CoronitaParticipant[quote=FlyerInHi]exsdgal, why leave the old components in place. The perfectionist in me doesn’t like this for aesthetic reason. You did the work already, it’s just a pipe and elbow extra.

Flu, I recommend a Kevlar shield. It stays nice and cool.

Why get a threaded valve?Just get the solder kind. So much easier, and you have more room for adjustment. I never replaced a regulator…do they all have threaded connections? I know that you want future serviceability but once you learn how to solder, that is the serviceability. Threads get corroded, the sizes will no longer match, etc… just buy everything new and solder..

Or is there is no leak, just leave good enough alone. I think flood control smart valves are coming to maket.

I’m pretty sure you don’t have home warranty. But for those who do, the insurance company (such as American Home Shield) should repair for the deductible. They may refuse to do the regulator if it’s still working but the valve would be replaced.[/quote]

Hmm I do have a home warranty on my primary. Didn’t even think of that….

January 18, 2017 at 12:16 PM #804963FlyerInHi

Guest[quote=flu]

Hmm I do have a home warranty on my primary. Didn’t even think of that….[/quote]

There you go. I had American Home Shield on a newly purchased condo (seller paid for 1 year insurance). They replaced the main valve in water heater closet for $75 deductible. There was no regulator at the condo itself. The plumber did a great job.

January 18, 2017 at 9:14 PM #804970ltsddd

Participant[quote=harvey]How much would a plumber charge to do this?[/quote]

$500 for parts + labor is about right.

January 19, 2017 at 2:40 AM #804971ucodegen

Participant[quote=FlyerInHi]

Why get a threaded valve?Just get the solder kind. So much easier, and you have more room for adjustment. I never replaced a regulator…do they all have threaded connections? I know that you want future serviceability but once you learn how to solder, that is the serviceability.[/quote]The internal seals and diaphragms of a regulator do not like the type of heat you solder with. The unions make it easier to replace – since it is much more likely to fail than a copper pipe. The threads are brass, so they are less likely to corrode.January 19, 2017 at 10:22 AM #804973FlyerInHi

GuestTrue, ucodegen. I once soldered a ball valve and it became looser afterwards. I guess whatever inside go melted a little but it still works fine.

I use Moen positemp valves in showers and before soldering I have to remember to remove the cartridge so I don’t damage it.

It felt good when I did my first solder job. I felt manly, a studly stud. It was a complete bath remodel. I left the walls open for 1 week to make sure there were no leaks. Now I’m confident in my work. I have moved washer dryer,… lots of things.

So there is something to a man doing mechanical stuff. I admire women who can do stuff.

January 19, 2017 at 8:37 PM #804975La Jolla Renter

Participant[quote=FlyerInHi]That’s is so true! Anyone who has a science degree should figure things out logically. [/quote]

I do, and so agree with that logic. 🙂

Looking back, I would have done the plumbing myself while I was baby sitting all the other trades. Probably would have used pex and a manifold in the garage. I like the idea of being able to design with no joints from manifold to shutoffs under the sink.

I did install a direct to day light drain in the laundry closet on the second floor. Plumber thought that was a silly idea when you already have a pan and 1″ drain line.

January 19, 2017 at 11:41 PM #804977ucodegen

Participant[quote=FlyerInHi]

It felt good when I did my first solder job. I felt manly, a studly stud. It was a complete bath remodel. I left the walls open for 1 week to make sure there were no leaks. Now I’m confident in my work. I have moved washer dryer,… lots of things.So there is something to a man doing mechanical stuff. I admire women who can do stuff.[/quote]

I think some of the ‘studly’ stud feeling comes from self sufficiency, other part may come from taking somethings solid, making part of it liquid and joining things together – then it becomes one solid thing that does something. Maybe a bit of ‘creating’?Not enough women try to do these things. Possible reasons may be; people discourage them, not willing to try and take a risk – fail then learn, conditioning – through media and other sources..

-

AuthorPosts

- You must be logged in to reply to this topic.